Call: 08045477088

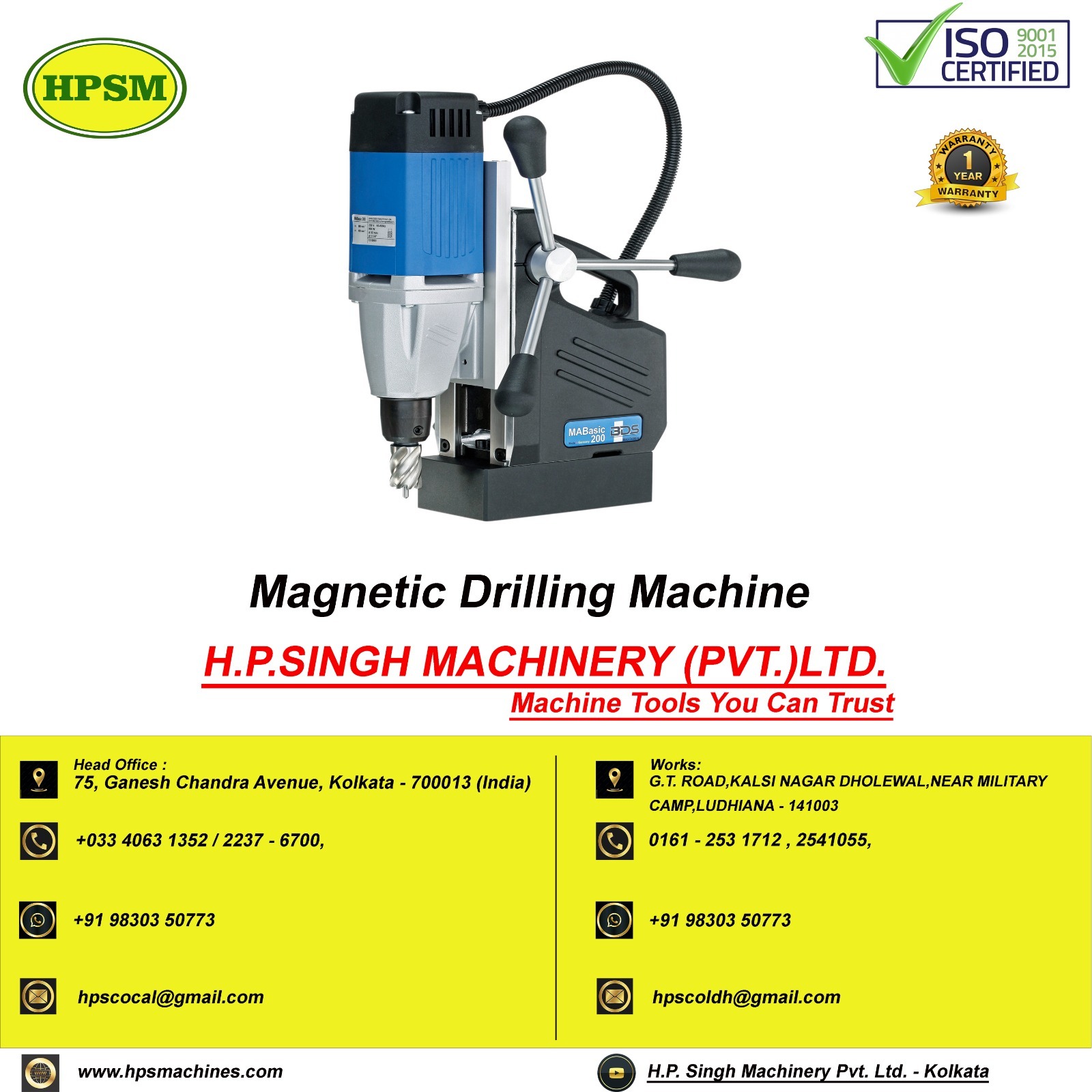

Magnetic Drilling Machine

12499.0 INR/Piece

Product Details:

- Motor Type Heavy Duty Copper Winding

- Tool Type Portable Magnetic Drill

- Features Powerful Magnetic Base, Overload Protection, Reversible Motor

- Size Standard

- Power Rating 1.5 kW

- Noise Level <85 dB db

- Operation Mode Manual

- Click to View more

X

Magnetic Drilling Machine Price And Quantity

- 12499.0 INR/Piece

- 1 Piece

- Integrated Coolant Bottle

- 2.5 m

- Keyed

- 13000 N

- IP54

- 120 mm

- 12-35 mm

- Electromagnetic

- 10-20 mm

- 50 mm

- 35 mm

Magnetic Drilling Machine Product Specifications

- 6 months

- 1500 W Watt (W)

- Powerful Magnetic Base, Overload Protection, Reversible Motor

- 14 kg Kilograms (kg)

- High-grade Steel and Aluminum Alloy

- Manual

- Electric

- 1.5 kW

- 330 x 220 x 500 mm Millimeter (mm)

- Magnetic Drilling Machine

- Portable Magnetic Drill

- Core Drilling/Cutting Metal Surfaces

- Standard

- Heavy Duty Copper Winding

- Industrial

- 50 Hz Hertz (HZ)

- <85 dB db

- Yes

- Blue

- 230 V Volt (V)

- Integrated Coolant Bottle

- 2.5 m

- Keyed

- 13000 N

- IP54

- 120 mm

- 12-35 mm

- Electromagnetic

- 10-20 mm

- 50 mm

- 35 mm

Magnetic Drilling Machine Trade Information

- 1 Days

- All India

Product Description

Discover the must-have Magnetic Drilling Machine, renowned for its powerful 1500W motor, 13000 N magnetic adhesion, and decorated with favorable reviews. Engineered with high-grade steel and aluminum alloy, this gorgeous blue tool handles up to 35 mm drilling diameter and 50 mm depth with robust precision. Value-packed with overload protection, variable speed, and reversible motor, its ideal for industrial applications and export. Enjoy reliable performance in core drilling or cutting metal surfacesfavored by professionals and manufacturers across India. Backed by a 6-month warranty for peace of mind.

Versatile Applications & Industrial Performance

This Magnetic Drilling Machine shines in both general and specific industrial uses. Its electromagnetic base ensures secure placement for core drilling or cutting metal surfaces in fabrication shops, construction, or maintenance environments. Widely used for pipework, structural steel, and machinery repairs, it simplifies demanding tasks. Its application methodmanual operation coupled with variable speed settingsdelivers precision on metal, making it a staple for professionals seeking consistent, high-quality results in commercial and general purpose scenarios.

Professional Packaging & Efficient Delivery

Each Magnetic Drilling Machine is packaged securely to ensure its safe arrival and flawless condition. Order completion is streamlined by our experienced team, coordinating logistics with trusted transport services. For export orders, we arrange shipping from major Indian FOB ports, adhering to global standards. Average delivery time ranges from one to two weeks, depending on your specific location, guaranteeing prompt fulfillment for urgent project requirements. Our reliable packaging process minimizes risks during transport, maintaining product integrity every step of the way.

Versatile Applications & Industrial Performance

This Magnetic Drilling Machine shines in both general and specific industrial uses. Its electromagnetic base ensures secure placement for core drilling or cutting metal surfaces in fabrication shops, construction, or maintenance environments. Widely used for pipework, structural steel, and machinery repairs, it simplifies demanding tasks. Its application methodmanual operation coupled with variable speed settingsdelivers precision on metal, making it a staple for professionals seeking consistent, high-quality results in commercial and general purpose scenarios.

Professional Packaging & Efficient Delivery

Each Magnetic Drilling Machine is packaged securely to ensure its safe arrival and flawless condition. Order completion is streamlined by our experienced team, coordinating logistics with trusted transport services. For export orders, we arrange shipping from major Indian FOB ports, adhering to global standards. Average delivery time ranges from one to two weeks, depending on your specific location, guaranteeing prompt fulfillment for urgent project requirements. Our reliable packaging process minimizes risks during transport, maintaining product integrity every step of the way.

Specifications

|

Drilling Diameter |

50 mm |

|

Type of Drilling Machine |

Pillar |

|

Spindle Travel |

50 mm |

|

Warranty |

6 months |

|

Weight |

15 |

|

Size |

32 40 |

|

Tapping Capacity |

10 mm |

|

Country of Origin |

Made in India |

FAQs of Magnetic Drilling Machine:

Q: How does the Magnetic Drilling Machine ensure safety and operational longevity?

A: The machine features overload protection and a powerful magnetic base, which safeguard both the user and the equipment. Its heavy-duty copper winding motor offers robust performance and longevity in demanding applications.Q: What are the specific industrial uses of this Magnetic Drilling Machine?

A: This tool excels at core drilling and cutting metal surfaces, commonly used in fabrication shops, construction sites, and for heavy machinery maintenance. Its versatility allows for both general purpose and specialized industrial applications.Q: When can I expect delivery after placing an order?

A: Delivery typically takes one to two weeks after order completion, depending on your location and chosen transport services. Our efficient logistics process ensures that shipments are dispatched promptly from major Indian ports.Q: Where is this Magnetic Drilling Machine manufactured and supplied?

A: The machine is proudly made in India and supplied/exported by renowned manufacturers to clients across different markets, with a strong reputation for quality and reliability in industrial sectors.Q: What benefits does the integrated coolant bottle provide during operation?

A: The integrated coolant bottle ensures efficient cooling of the drill bit, reducing heat build-up, enhancing operational safety, and extending the lifespan of both the tool and drill accessories during rigorous metalworking.Q: How should the Magnetic Drilling Machine be applied for best results?

A: For optimal performance, mount the electromagnetic base securely on a clean, flat metal surface. Use the keyed chuck for precise bit placement, adjust the variable speed as needed, and engage the cooling system during extended drilling.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry